Tank Level Control System

Tank level control system. The status of the system is communicated to the computer by MPI and is viewed and remotely controlled by the user through the HMI. The control of liquid levels for example in process tanks is an important function. Water Tank Level Control System Automatically controlling water levels in a water storage tank is important for keeping your operation running efficiently.

You can eliminate the use of electronic float switches for water storage tanks with water tank level sensors the best float system for a water tank or well water holding tank. IoT Based Water Tank Level Control System Using PLC Abstract. Ad Our experts are competent on all questions relating to level measurement.

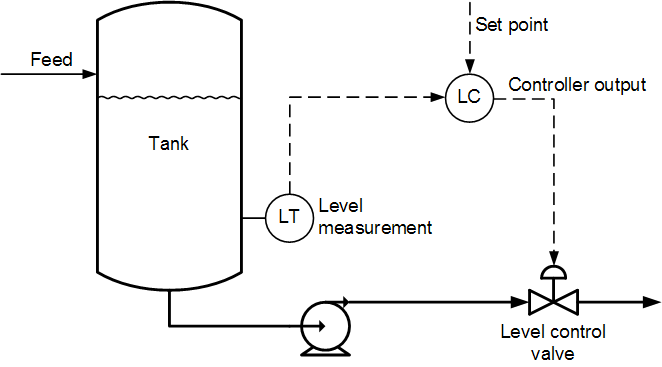

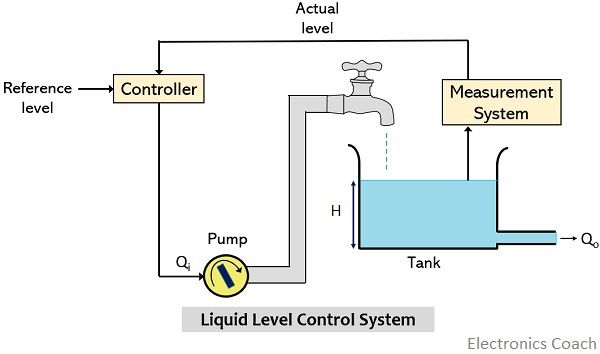

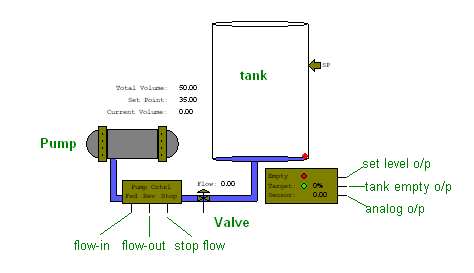

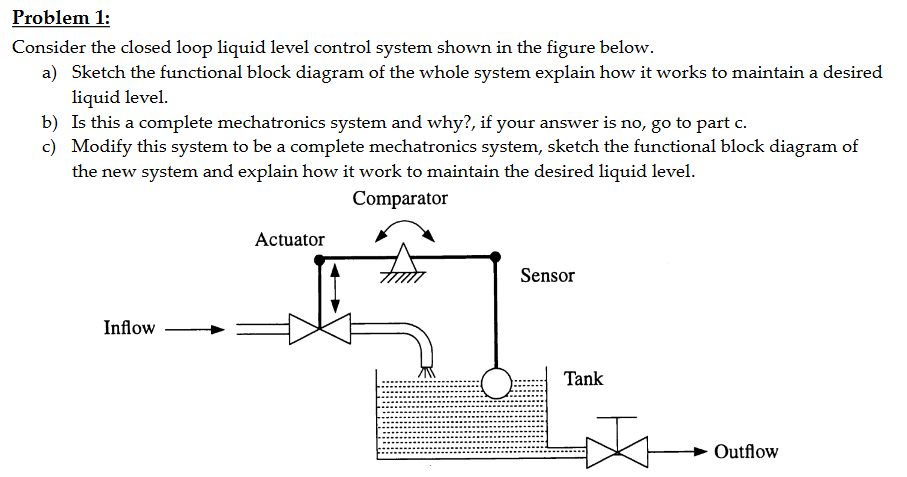

Non-adjustable onoff level control Figure 831 The final control element may be a pump which is switched onoff or a valve which is openedclosed. 31 The Water Tank Level Control System The system shown in Fig 31 consists of 16 blocks out of which 3 are subsystems. It has Pump Running Low Level High Level Signals.

The overall mechanical design of the system and the PLC system design and implementation. The crucial components of the water level control system are as follows. The unstable condition normally contributes to damage of devices and equipments of a process plant.

Adjustable onoff level control. This system consists of two tanks with orices and level sensors at the bottom of each tank a pump and a water basin. The level sensor communicates the present level of the tank to the PLC.

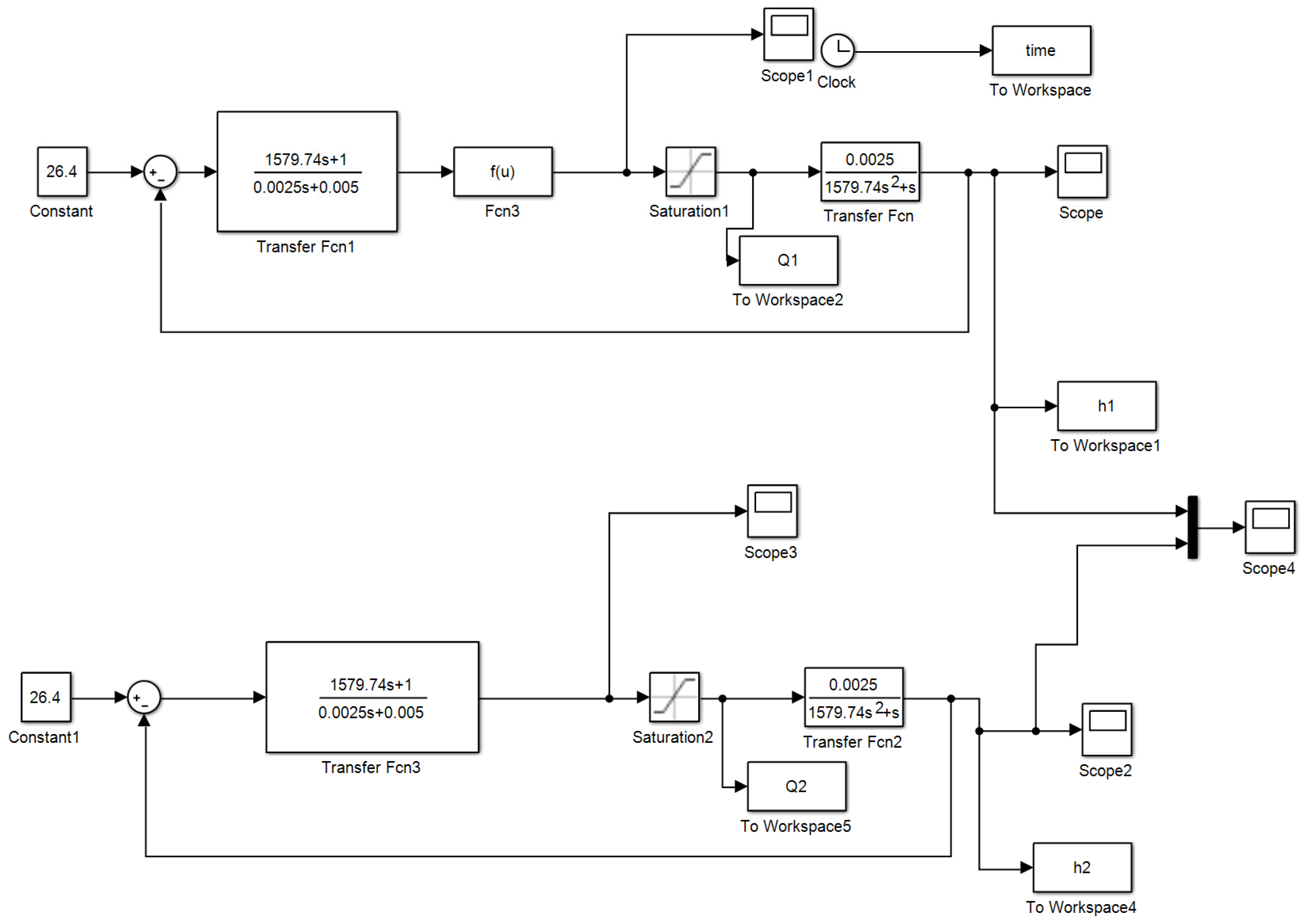

The input of the system consists of a square wave that is generated using the signal generator block. The inlet flow rate is not measured but there is a level measurement that shows how much fluid has been added to the tank. A range of level control systems and methods are commonly used in industry.

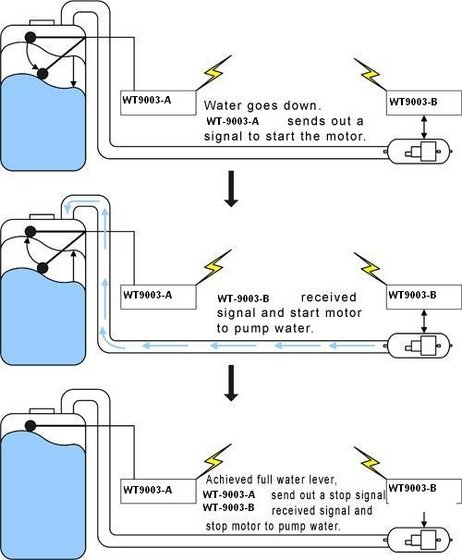

An electronic water level controller can automatically control the water level inside a water tank. Our water tank level control system uses well level sensors to manage and control water level in your water tank.

This system consists of two tanks with orices and level sensors at the bottom of each tank a pump and a water basin.

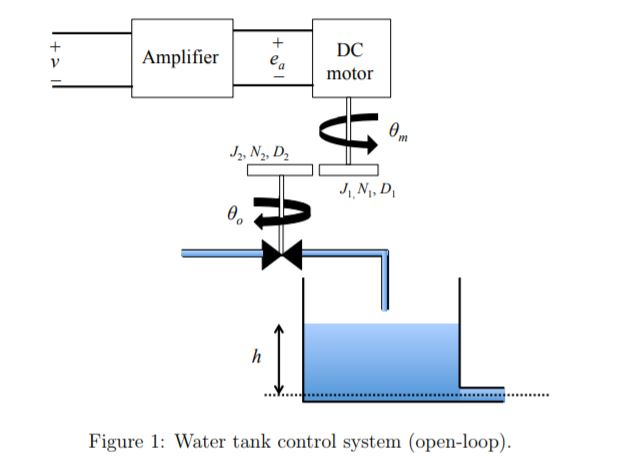

One activated when fluid levels reach a high point and one when they. The schematic drawing in Figure 1 represents the model of a two degree-of-freedom DOF state-coupled water tank system. 31 The Water Tank Level Control System The system shown in Fig 31 consists of 16 blocks out of which 3 are subsystems. There are three main methods of achieving level control. And implementation of a PLC-based water level control system. This panel contains LEDs to show the status of the water level control. IoT Based Water Tank Level Control System Using PLC Abstract. The swinging arm attached to the input valve of the WC water tank allows water to flow into the tank until the float rises to a point that closes the valve. Pump Down Tank Level Control Systems For pump down applications or those where water or other liquids must be removed from a tank when levels become too high thus avoiding dangerous pressure build-up or overflow two independent float switches or other level sensors may be used.

Non-adjustable onoff level control Figure 831 The final control element may be a pump which is switched onoff or a valve which is openedclosed. Also known as a storage tank used to hold the desired amount of fluid. IoT Based Water Tank Level Control System Using PLC Abstract. The crucial components of the water level control system are as follows. Internet of Things IoT has been widely used in various applications such as health and safety smart homes greenhouses and industrial application. Level Tank model -1order Nonlinear Model The following model is even more accurate. It has Pump Running Low Level High Level Signals.

Post a Comment for "Tank Level Control System"